2026 Top Machine Tools Trends You Need to Know?

As we approach 2026, the landscape of Machine Tools is evolving rapidly. Experts emphasize the need for innovation and adaptation. According to Dr. John Smith, a renowned figure in the Machine Tools industry, "The future of manufacturing hinges on the advancements in Machine Tools." This statement reflects the critical role these tools will play in shaping the manufacturing sector.

In the coming years, we expect to see trends that focus on automation, sustainability, and smart technology integration. Machine Tools will increasingly incorporate AI and IoT, enhancing efficiency and precision. However, this shift also brings challenges. Companies must invest in training to keep their workforce skilled. Many businesses struggle to balance technological advancements with human expertise.

It’s crucial to consider how Machine Tools will adapt to changing demands. For example, the need for customization in production is growing. Yet, some industry professionals are unsure if existing machines can keep up. The transition may not be smooth, and gaps in knowledge might hinder progress. As we look ahead, it’s clear that the Machine Tools sector is at a pivotal moment, requiring both introspection and forward-thinking strategies.

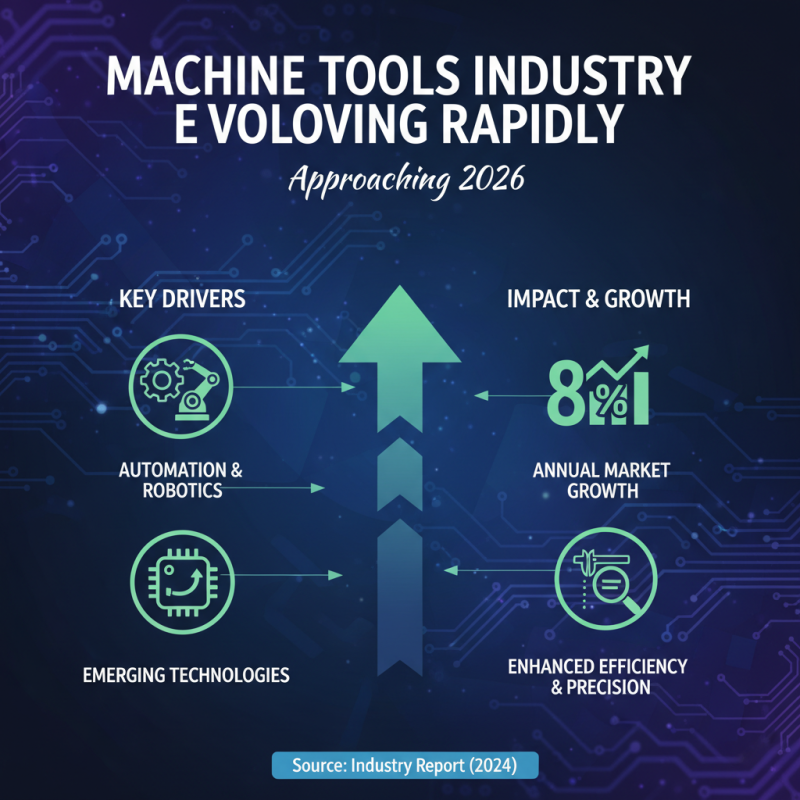

Emerging Technologies in Machine Tools for 2026

The machine tools industry is evolving rapidly as we approach 2026. Emerging technologies are reshaping how machining processes are executed, driving efficiency and precision. According to a recent report, the market for advanced machine tools is expected to grow by 8% annually. This growth is attributed to automation and robotics integration.

One significant trend is the increasing use of artificial intelligence. AI-driven systems can analyze vast amounts of data. They help identify inefficiencies and optimize production schedules. A study showed that AI can improve operational efficiency by up to 30%. However, the complexity of these systems can lead to unexpected challenges. Companies need to train their workforce to adapt to these advancements.

Another noteworthy development is additive manufacturing. This technology allows for creating complex geometries that traditional methods cannot achieve. In fact, statistics indicate that the additive manufacturing market will reach $35 billion by 2026. This shift raises questions about workforce skill gaps and material limitations.

Tips: Invest in employee training to avoid skill stagnation. Embrace a culture of constant learning. This proactive approach keeps your team adaptable in a rapidly changing environment.

The Impact of Automation and AI on Manufacturing Processes

Automation and artificial intelligence (AI) are transforming manufacturing processes. These technologies streamline operations, boost efficiency, and enhance precision. Machines can now perform tasks that once required human intervention. This shift reduces labor costs and minimizes errors in production. However, reliance on automation raises concerns about job displacement. Many workers fear losing their jobs to machines.

AI algorithms make quick decisions based on vast data sets. They can optimize manufacturing workflows and predict maintenance needs. For example, predictive maintenance helps avoid unexpected downtimes. Yet, implementing AI requires substantial investment and technical expertise. Not every organization is prepared for such a change. There are risks involved in adopting new technologies, including cybersecurity threats.

Training the workforce is crucial. Employees need to adapt to new roles alongside machines. This can create tension in the workplace. Some might resist change, fearing they lack the necessary skills. Balancing human and machine interaction is essential. The future of manufacturing hinges on how well businesses manage this integration. Embracing automation and AI offers immense opportunities, but challenges remain.

Sustainability Trends in Machine Tool Production and Use

Sustainability is shaping the future of machine tool production. Manufacturers are increasingly adopting green practices. This shift reduces waste and lowers energy consumption. The integration of renewable energy sources is becoming common. Solar and wind energies are now part of the equation. These changes, however, require upfront investment, which can be challenging for smaller companies.

The focus on sustainable materials is growing. Many are exploring biodegradable and recyclable components. This transition can initially seem costly. The challenge lies in balancing quality and sustainability. Many traditional practices are hard to shake off. Also, the industry often struggles with sourcing sustainable supplies consistently.

Recycling old machine tools is another critical trend. Companies are beginning to recognize the potential in refurbished machinery. However, not all machines may be suitable for reuse. This raises questions about quality control. The journey towards sustainability is complex. It demands constant innovation and open-mindedness. Many manufacturers still have work to do in achieving true sustainability. There’s always room for improvement, and reflection on practices is essential.

2026 Top Machine Tools Trends You Need to Know - Sustainability Trends in Machine Tool Production and Use

| Trend | Description | Impact on Sustainability | Projected Growth |

|---|---|---|---|

| Energy Efficiency Innovations | Advancements in energy-saving technologies within machine tools. | Reduction in energy consumption during operation. | 20% annual increase by 2026. |

| Recyclable Materials | Use of recyclable and bio-degradable materials in production. | Reduced waste and lower environmental impact. | 15% increase in adoption rates. |

| Smart Manufacturing and IoT | Integration of Internet of Things for real-time monitoring and efficiency. | Optimized resource utilization and minimized waste. | 25% annual growth expected. |

| Carbon Neutral Technologies | Development of machines that are carbon neutral in their operation. | Significant reduction in carbon footprint of production processes. | 15% growth in market share. |

| Automation and Robotics | Increased use of robotic automation to enhance productivity. | Higher precision leading to less material waste. | 20% projected increase in utilization. |

Key Players and Innovations Shaping the 2026 Machine Tools Market

The machine tools market is evolving rapidly. Key players are focusing on automation and smart technologies. Reports suggest that the global machine tools market will reach $80 billion by 2026. Innovations are reshaping manufacturing processes.

One notable trend is the integration of IoT and AI in machine tools. These technologies enhance efficiency but may require a learning curve for operators. Machine tools are becoming smarter but can lead to skill gaps in the workforce. It’s essential to consider training programs for staff to bridge this divide.

Here’s a tip: invest in upskilling your team to adapt to these advancements. The focus on sustainability is also significant. Many companies are seeking eco-friendly manufacturing processes. However, transitioning to greener practices can be challenging. It requires substantial investment and a shift in mindset. Evaluate your long-term goals for sustainability carefully.

Future Skills and Workforce Development in the Machine Tool Industry

The machine tool industry is evolving rapidly. Future skills are essential for workers. With automation and AI taking root, the need for skilled labor grows. Workers require knowledge in programming and operating advanced machinery. These skills are not just an addition; they are necessary for job survival.

Training programs must adapt. Traditional methods may not suffice. Courses need to focus on hands-on experiences. Virtual simulation can enhance learning. Such tools allow workers to practice without real-world risks. However, the challenge lies in keeping curriculums updated with fast-paced technology changes.

Collaboration between companies and educational institutions is crucial. This partnership can bridge skill gaps. Yet, there is a risk of misalignment between industry needs and training provided. Companies may focus on immediate results. Long-term workforce development requires more investment and effort. Finding the right balance is essential for sustainable growth in the machine tool sector.

Related Posts

-

Exploring the Advantages of Integrating Lathe and Milling Machine in Modern Manufacturing

-

How to Maximize Efficiency with a Cnc Tool Room Lathe in Your Workshop

-

Setting the Benchmark: Understanding CNC Tool Manufacturing Standards and Their Global Impact

-

How to Choose the Best Measuring Tools for Accurate Results in Your Projects

-

How to Choose the Best Milling Equipment for Your Business in the 2025 Global Market

-

5 Reasons Why Tool Room Mills are Essential for Modern Manufacturing