What is a Center Bearing and How Does It Work?

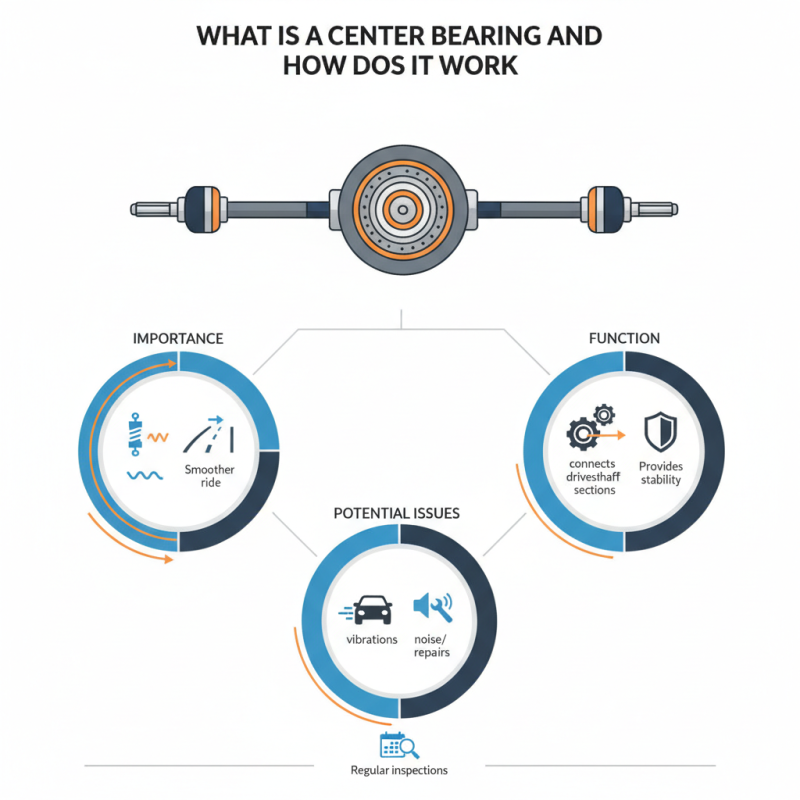

The Center Bearing plays a crucial role in vehicle dynamics. According to Dr. Mark Thompson, a leading expert in automotive engineering, "The Center Bearing is essential for supporting the driveshaft." This component helps reduce vibrations and ensures a smoother ride.

Understanding how the Center Bearing functions is vital for vehicle maintenance. It connects the two sections of the driveshaft, providing stability. Many drivers overlook it until issues arise. Common problems include vibrations or noise. These signs can indicate a failing Center Bearing, leading to costly repairs if neglected.

Discussing the Center Bearing reveals both its importance and its potential for malfunction. Regular inspections can prevent major breakdowns. Yet, many drivers do not prioritize this. Reflecting on this aspect can improve vehicle safety and performance. Awareness is key in automotive care.

What is a Center Bearing?

A center bearing is a crucial component in vehicles with multi-piece drive shafts. It supports the center of the drive shaft, helping to maintain proper alignment and reduce vibrations. This bearing allows for flexibility as the drive shaft rotates. It also absorbs shocks and acts as a connection point between the two halves of the shaft.

Many drivers overlook the center bearing's importance. However, its failure can lead to significant issues. Vibrations may increase, and handling can become unstable. Many enthusiasts may ignore or forget to check this part during maintenance. A worn center bearing can lead to noise. It can also cause premature wear in surrounding components. Regular inspection is essential, yet it is often neglected.

The center bearing consists of a rubber insulator that dampens vibrations and a metal casing. The design allows for movement while supporting the shaft. Replacing a failing center bearing can restore comfort and stability. However, many wait too long to address the issue. This delay often leads to more significant repairs down the road. Recognizing early signs like noise or vibration can save drivers from costly problems later on. Awareness and attention to this small but vital part can improve overall vehicle performance.

The Functionality of Center Bearings in Vehicles

A center bearing plays a vital role in vehicle drivetrains. It supports the driveshaft and ensures proper alignment. This component is crucial for smooth operation. According to industry reports, issues with center bearings can lead to significant vibrations and noise. These problems often indicate a more extensive drivetrain issue.

In cars, the center bearing acts as a fulcrum between the two sections of the driveshaft. It helps to manage the angles that occur during motion. When this bearing deteriorates, symptoms like vibrations can emerge at certain speeds. A study showed that over 30% of drivers report experiencing unusual noises related to their center bearings. Ignoring these signs could lead to costly repairs down the line.

Regular maintenance is key to preserving the lifespan of center bearings. However, many vehicle owners overlook this task. Studies suggest that only 40% of drivers routinely check this part. The lack of awareness can lead to unexpected failures. Awareness and proactive checks can enhance vehicle performance. Drivers should take a moment to consider the condition of their center bearings during maintenance.

Center Bearing Functionality in Vehicles

This chart illustrates the key performance metrics associated with center bearings in vehicles. It includes vibration levels, noise levels, load capacity, durability measured in cycles, and installation time, highlighting the importance of these factors in ensuring optimal functionality of center bearings.

Components of a Center Bearing Assembly

A center bearing is a crucial part of a vehicle's drivetrain. It supports the drive shaft, allowing it to rotate smoothly. Understanding its components helps in grasping its role.

The center bearing assembly includes several key elements. The bearing itself is often made of metal and has a specific shape. This allows it to hold the drive shaft securely. Cushions or rubber mounts are commonly attached. These help absorb vibration, making the ride smoother. You might notice these features during a repair. They involve more connections than one originally expects.

However, some may overlook the importance of maintenance. Over time, wear can affect these components. Neglected parts lead to noise or vibration during driving. This is frustrating for many vehicle owners. Regular checks can prevent such issues from escalating. Understanding your vehicle's center bearing assembly is essential for better performance.

What is a Center Bearing and How Does It Work? - Components of a Center Bearing Assembly

| Component | Function | Material | Typical Size |

|---|---|---|---|

| Center Bearing | Supports driveshaft and reduces vibrations | Rubber, Steel | 3-5 inches diameter |

| Mounting Bracket | Holds the center bearing in place | Steel | Varies by vehicle |

| Bearing Seal | Prevents contaminants from entering the bearing | Rubber | 1-3 inches diameter |

| Universal Joint | Allows the driveshaft to flex and pivot | Steel | 1-2 inches |

Common Issues and Maintenance Tips for Center Bearings

Center bearings play a crucial role in vehicle drivetrain systems. They support the driveshaft, ensuring proper alignment and smooth operation. However, like any mechanical component, they can encounter issues. Common problems include excessive wear and noise. Drivers may notice vibrations or clunking sounds during acceleration. These signs can indicate a failing center bearing, necessitating immediate inspection.

Regular maintenance is vital for longevity. It's essential to check the center bearing for any signs of damage or play. Ensuring that the bearing is adequately lubricated will help reduce friction and wear. Moreover, maintaining proper alignment of the driveshaft can prevent undue stress on the bearing. Ignoring these maintenance tasks may lead to more severe issues down the line. Addressing small problems early can save time and money.

Pay attention to the environment, too. Road conditions can contribute to premature wear. Driving on rough roads increases the risk of damage. You might find it helpful to regularly inspect your vehicle, focusing on the driveshaft area. Keeping a close eye on these components can lead to safer and smoother drives.

The Role of Center Bearings in Drive Shaft Systems

Center bearings play a crucial role in drive shaft systems, serving as support for the drive shaft. They ensure that the shaft remains aligned and can rotate smoothly. According to industry reports, about 30% of drive shaft failures are related to bearing issues. This emphasizes the importance of proper maintenance and understanding of center bearings.

These bearings help reduce vibration and noise. They absorb shock and support the driveshaft, which is essential for vehicle stability. When center bearings wear out, it can lead to excessive vibrations. This can affect ride quality and vehicle performance. A worn bearing may also contribute to uneven tire wear and increased fuel consumption.

Regular inspection of center bearings is important. Signs of wear include unusual noises and vibrations. Ignoring these signs can lead to costly repairs. A proactive approach can extend the lifespan of the entire drive shaft system. Understanding center bearings allows vehicle owners to maintain optimal performance.